Equipment for preliminary cleaning of seed and other material

Grain cleaner (pneumatic channel) was awarder the EUREKA 2002 gold medal, featured in CANADA's Farm Progress 2015 and other fairs.

Preliminary seed cleaning is one of the basic actions taken in the course of preparing seed-grain for proper storing.

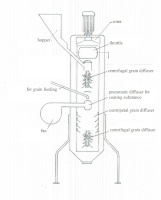

Our centrifugal winnowing machine - grain cleaner (pneumatic channel) has been designed to clean seeds of corn, pulse crops, rape, seed grasses, plastics, sawdust, frozen fruit etc., from light litter and smaller seeds.

Good preliminary cleaning is achieved at 50-60% efficiency. For sowing, it is recommended for performance 5-8% maximum capacity for wheat.

Maximum efficiency for wheat:

WS 36 - machine with the capacity of - 36 b/h weight - 35 lb engine - 0,34 HP

WS 110 - machine with the capacity of - 110 b/h weight - 60 lb engine - 0,50 HP

WS 330 - machine with the capacity of - 330 b/h weight - 110 lb engine - 0,75 HP

WS 730 - machine with the capacity of - 730 b/h weight - 198 lb engine - 2,0 HP

WS 1500 - machine with the capacity of - 1500 b/h weight - 265 lb engine - 3,0 HP

WS 2400 - machine with the capacity of - 2400 b/h weight - 395 lb engine - 5,0 HP

WS 3500 - machine with the capacity of - 3500 b/h weight - 550 lb engine - 7,5 HP

WS 4500 - machine with the capacity of - 4500 b/h weight - 795 lb engine - 10,0 HP

Larger grain clearn on request

When cleaning difficult materials, eg plastics, sawdust, frozen fruit etc. it is advisable to mount one more module and use 0,6-7% efficiency.

In order to prepare the seed for sowing, a yield of 5-8% is recommended.

Cleaning screw conveyor

The cleaning screw conveyor T-015, has been designed in order to transport the grainy material with the possibility of preliminary cleaning. In the lower part of the enclosure of the conveyor there are used interchangeable cleaning sieves.

Equipment:

8 sieves with round holes

Rotary outflow

The conveyor can be set to three different rotations of the auger spiral

Performance for wheat:

It is depending on the gear - 220, 235, 250, 265 or 310 b/h. It cleans better with lower efficiency.

Minimal length: 112 inch

Maximal length : 260 inch

Conveyor of length 160 inch weights 77 kg, uses engine of power 2.0 HP.

Seed coating machine

The coating substance that comes from a nozzle into a little holes sieve is dispersed by the air coming from the blower. Evenly dispersed seed is evenly treated with coating substance. Falling seed is set into oblique and roatary motion. Closed circulation of air saturated with coating, additionally covers pores of seed and reduces environmental pollution.

A grain auger receiving coated seed, smoothens its coverage.

Furance

Free-standing Sosnowski's Furnace has been designed in order to provide high esthetic and utility value.

The furnace is portable, easy to assembly; convenient to be transported and set in any chosen location and circumstances, such as picnic, excursion, etc. It allows to comfortably prepare dishes of meat, fish, baked potatoes, apples, warm up pizza or roast sausages.

Some of the users prefer to indulge in the sensational view of flames, the warmth and beauty of which bring the feeling of joy and relax.

Even at a very close distance to the furnace there is no danger of sparks; the burning process in our furnace is stable and almost entirely smokeless.

As preparing food on the turn-table plate above the furnace, or roasting over the ash-pan eliminates harmful substances from the smoke; it is highly recommended to bake potatoes or apples in the ash-pan.

The furnace can be used both outdoors and in the interiors with open fireplaces.

There are produced three sizes of furnaces with different diameter: Family - S - 15 inch, Feast - M – 18 inch and Camping - L - 23 inch of diameter - the biggest one.

The furnace consists of a base that protects the grass and the floor from burning. It is however recommended that an additional layer of thermoprotective coat of radius ca. 25% larger than the one of the base is placed underneath.

The air flowing through the vaults in the bowl of the furnace, stimulates the flame. Vaults in the upper part of furnace also support the process of burning.

Pieces of wood, that have not been burnt fully, fell into the ash-pan where the process of burning completes.

It is recommended to use dry timber of broadleaved trees of 5 – 8 inch of length, 2 – 5 inch thick. The pieces of timber should be laid flat and at the central part of the furnace to minimize smoke. To start and stop the fire use thumb-thick pieces of timber.

The furnace is protected under the patented: US 7,900,623 B2; in Poland: P 203014, P 207898, P 208159, P 217181; in Europe EP 1895881.